Specification

which winding is better copper or aluminium

Source:Original

Editing:frank

Time:2022-02-28 17:52

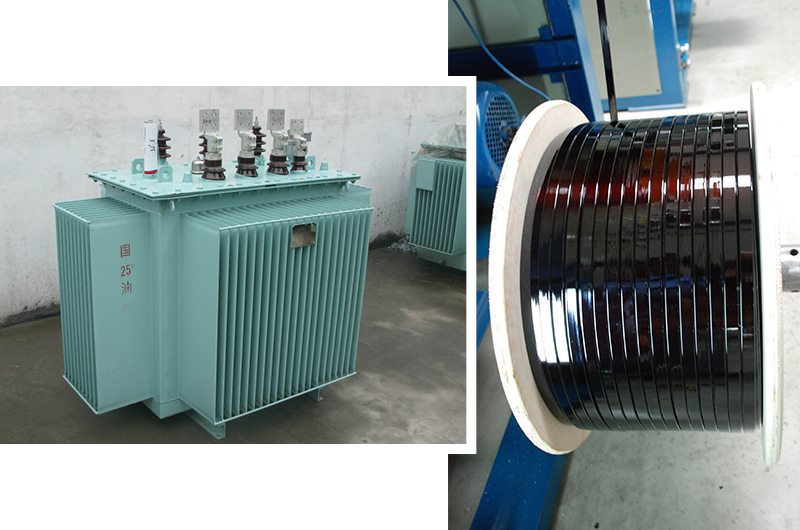

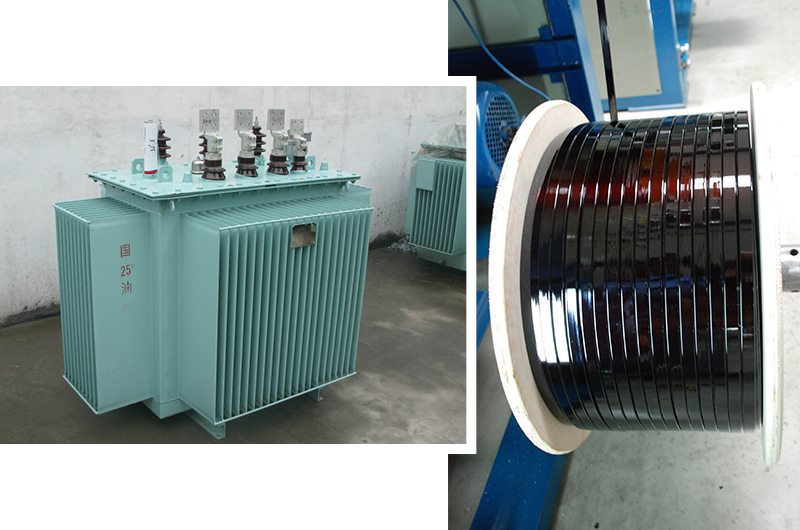

In recent years, with the wide use of aluminum flat winding wire in transformer industry, copper flat winding wire and aluminum flat winding wire are widely used in dry-type distribution and voltage transformation

More and more attention has been paid to the performance comparison in. Among them, the long-term creep behavior of copper flat winding wire and aluminum flat winding wire is one of the important indexes of reliability and stability of copper and aluminum transformers. By testing the creep and conventional properties of enamelled copper and aluminum flat winding wires for dry-type distribution transformers, the reliability of copper and aluminum flat winding wires is evaluated and analyzed, which plays a certain reference role for transformer manufacturers to understand the differences between copper and aluminum transformers and select reliable materials and technologies.

When the creep test temperature is 160 ℃, the following conclusions can be obtained through the comparative study on the withstand stress, creep stage, surface morphology, conductor size and electrical properties of copper / aluminum flat winding wire:

1) When the creep test temperature is 160 ℃, the withstand stress of aluminum flat winding wire is significantly lower than that of copper flat winding wire;

2) When the creep test temperature is 160 ℃ and the withstand stress is 35 MPa, the creep behavior of aluminum flat winding wire is more obvious than that of copper flat winding wire;

(3) the test results of conductor size show that under the same test conditions, the section size shrinkage of aluminum flat winding wire sample is more obvious than that of copper flat winding wire sample;

(4) the calculation results of DC resistivity show that under the same test conditions, the conductivity degradation of aluminum flat winding wire is more obvious than that of copper flat winding wire.

It can be inferred that under the same creep test conditions, the creep resistance of aluminum flat winding wire is significantly worse than that of copper flat winding wire.

More and more attention has been paid to the performance comparison in. Among them, the long-term creep behavior of copper flat winding wire and aluminum flat winding wire is one of the important indexes of reliability and stability of copper and aluminum transformers. By testing the creep and conventional properties of enamelled copper and aluminum flat winding wires for dry-type distribution transformers, the reliability of copper and aluminum flat winding wires is evaluated and analyzed, which plays a certain reference role for transformer manufacturers to understand the differences between copper and aluminum transformers and select reliable materials and technologies.

When the creep test temperature is 160 ℃, the following conclusions can be obtained through the comparative study on the withstand stress, creep stage, surface morphology, conductor size and electrical properties of copper / aluminum flat winding wire:

1) When the creep test temperature is 160 ℃, the withstand stress of aluminum flat winding wire is significantly lower than that of copper flat winding wire;

2) When the creep test temperature is 160 ℃ and the withstand stress is 35 MPa, the creep behavior of aluminum flat winding wire is more obvious than that of copper flat winding wire;

(3) the test results of conductor size show that under the same test conditions, the section size shrinkage of aluminum flat winding wire sample is more obvious than that of copper flat winding wire sample;

(4) the calculation results of DC resistivity show that under the same test conditions, the conductivity degradation of aluminum flat winding wire is more obvious than that of copper flat winding wire.

It can be inferred that under the same creep test conditions, the creep resistance of aluminum flat winding wire is significantly worse than that of copper flat winding wire.

RELATED READ:

- Foil for electrolytic capacitors2015.3.19

- Copper-Clad Aluminum Wire (CCA)2015.3.19

- 5052 aluminum strip for shutters2015.3.19

- Application of aluminum semi-finished products in e2015.3.19

- Copper clad aluminum enamelled round wire2015.3.19