Enameled Aluminium Round Wire

Enameled aluminum magnet round wire strip

Class 180/200/220 enamelled aluminum (copper) round wire Feature

Class 180/200/220 enamelled aluminum (copper) round wire Feature

Product introduction:

Enameled aluminum (copper) magnet round rectangular wires strips is made of oxygen free (copper) rod or electrical round aluminum rod by a certain size of the die drawing or extrusion of the wire, the insulation paint through many times of the winding wire. Mainly used in winding of transformers, motors, generators, and various electrical devices.

Product Range:

Wires strip thickness a: 0.80--8mm

Wire strip width b: 2.0--16.0mm

Recommended width ratio of conductor: 1.4<b/a<8.0

Temlierature Class (C) : 130, 155, 180, 200, 220

Color : natural color,red,blue, green and so on

liackage : PT-25 PT-30 PT-60 PT-90 PT-200,PT-270, wooden bobbin and according to customer requirements

Special size can be made with discuss.

Temlierature Class (C) : 130, 155, 180, 200, 220

Color : natural color,red,blue, green and so on

liackage : PT-25 PT-30 PT-60 PT-90 PT-200,PT-270, wooden bobbin and according to customer requirements

Special size can be made with discuss.

Standard :

Applicable standard or part of the reference standard :

GB/T6109/IEC60317-0-1

GB/T23312/IEC60317-0-3

MW76-A

MW35-A

.jpg)

.jpg)

Aluminum (copper) Wires Strips:

Enameled aluminum (copper) magnet round rectangular wires strips, is made by soft (copper) flat and soft (copper) flat wire in accordance with the provisions of the 5584.2-85 GB, 20℃when the resistivity is not greater than 0.01724Ω.mm2/m according to different mechanical strength requirements, the provisions of the semi hard (copper) conductor and aluminum conductor according to different mechanical strength requirements, semi hard (copper) conductor of non proportional C1Rp 0.2 (>100--180) N/mm2, C2Rp0.2 (>180--220) N/mm2, C3Rp0.2 (>220--260) N/mm2. 20 degrees of resistivity is less than 0.02801 Ω.mm2/m according to different electrical insulation requirements, selection of thin film 0.06--0.11mm or the thickness of the film 0.12--0.16mm. The heat adhesion paint package flat wire self-adhesive layer thickness is generally 0.03--0.06mm. Our company the loss tester for TD11 painting process for screening, the film fixed more hasten is perfect.

* If have special demand on paint thickness, please contact us as well.

Material :

Drawing or extruding bare (copper) (aluminum ) wire confirm to national standard, smooth surface, no defects .Good performance insulation varnish, polyester or polyester-imide insulation varnish as underlying coat, Polyamide-imide as superimposed coating.

Features of Enameled Round Aluminum Wire:

Low density allows coil weight reduction

Rapid heat dissipation

High cut through

Excellent heat shock

Perfect breakdown voltage

High heat resistance

Good solvent resistance

Product type:

130 grade Polyester enameled aluminum (copper) flat round wire

180 grade polyesterimide enameled aluminum (copper) flat round wire

200 grade Polyimide and polyimide mixed enameled aluminum (copper) flat round wire

120(155) grade polyvinyl acetal enameled aluminum (copper) flat round wire

Specs of Enameled aluminum (copper) magnet round rectangular wires strips

| Type | Polyesterimide |

Polyimide and polyimide mixed |

Polyvinyl acetal | Thermal bonding acetal |

|---|---|---|---|---|

| Temperature-resist grade | 180 | 200 | 120(155) | 120 |

| Property |

High heat resistance, good chemical resistance, hydrolysis resistance |

Excellent heat resistance, strong resistance to chemical solvents, good scratch resistance |

Excellent resistance to transformer oil, good resistance to scratch, excellent flexibility and adhesion, and good water resistance. |

In addition to all the performance with acetal, also can obtain good adhesion strength by the heating mode |

| Standard | GB/T7095.4-2008, IEC60317-28 | GB/T7095.6-2008, IEC60317-29 | GB/T7095.2-2008, IEC60317-18 | |

|

Testing Standard |

GB/T4074, IEC60851-1-6 | |||

Application of Enameled Round Aluminum Wire:

Transformers/ Heat-resistant motors/ UPS Power source/ Generators/ Refruigerating system;Other electrical devices in the coil windings

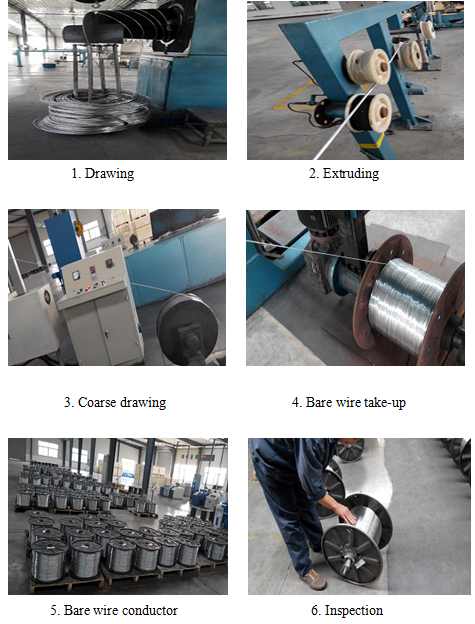

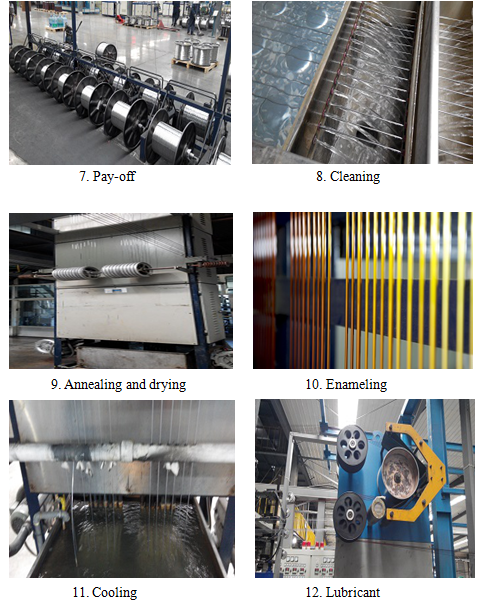

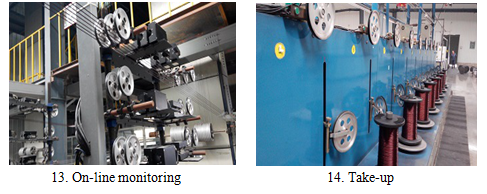

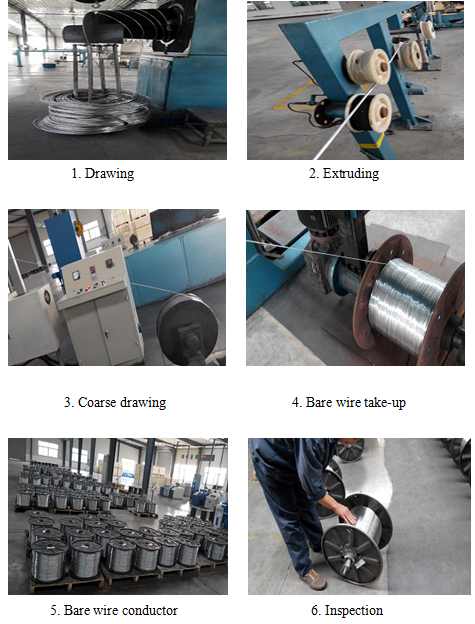

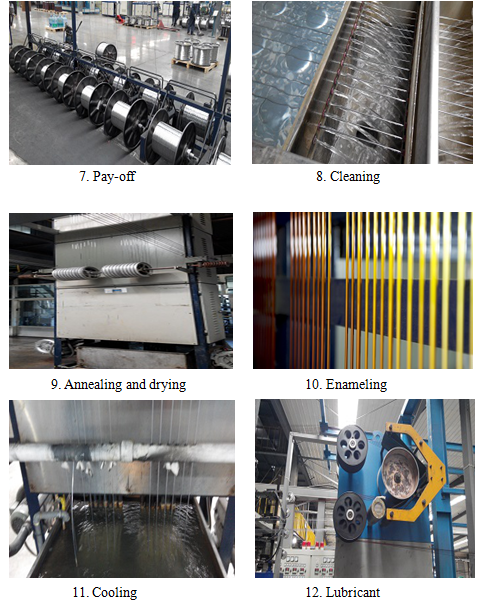

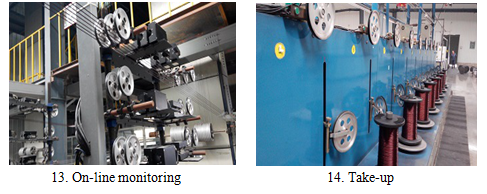

Production Process :

Packing Process :

Step 1 : Plastic film packaging, ensure neat and clean, dry;

2. Step 2 : Two kinds of paper box packaging, clean and tidy;

3. Step 3 : Wooden box packaging, the outside fixed with packing belt, safe and reliable;

Production Process :

Packing Process :

Step 1 : Plastic film packaging, ensure neat and clean, dry;

2. Step 2 : Two kinds of paper box packaging, clean and tidy;

3. Step 3 : Wooden box packaging, the outside fixed with packing belt, safe and reliable;

RELATED READ: