Transformer Strip

transformer aluminium strip

The Introduction of transformer aluminium strip

Transformer aluminum strip adopts the production process of casting and rolling, cold rolling, shearing and annealing. Compared with ordinary aluminum strips, its production is characterized by higher precision requirements. For example, many technical indicators such as surface quality and burr curling of aluminum strip are required to be very high, and a certain conductivity is required.

Transformer aluminum strips are divided into different Alloys, specifications and tempers according to their uses. The Alloys are: 1060, 1050, 1050A, 1060, 1070, 1070A, 1350, temper: O state. O represents the soft temper, and numbers can be used to represent the degree of softness and hardness, and the degree of annealing. The thickness is between 0.2--3.0mm, which is called: aluminum strip for dry-type transformer or aluminium foil for transformer .

aluminium strip for transformer winding or aluminium foil for transformer winding are made of high-quality pure aluminum, which has the characteristics of high conductivity, soft quality, smooth surface and no burrs. It has high requirements on many technical indicators such as electrical conductivity, burr curling, side bending and surface quality of aluminium strip and aluminium foil.

The Specifications and chemical composition of Aluminium strip for transformer

1) The Specifications of Aluminium strip for transformer

Alloy: 1060, 1050, 1050A, 1060, 1070, 1070A, 1350, etc. Temper: O Thickness: 0.2mm--3.0mm Width: 20mm-1650mm Inner diameter: 150mm, 305mm, 405mm, 505mm Outer diameter: 700-1200mm Inner core: paper tube, or according to customer requirements.

2)The chemical composition of the main alloy of Aluminum strip for transformer

| 1050 transformer aluminum strip Chemical composition(%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Zn | V | Ti | Others | Al | |

| Individual | Total | |||||||||

| max. 0.25 | max. 0.40 | max. 0.05 | max. 0.05 | max. 0.05 | max. 0.05 | max. 0.05 | max. 0.03 | max. 0.03 | - | min. 99.50 |

| 1060 transformer aluminum strip Chemical composition(%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Si | Fe | Cu | Mn | Mg | Zn | V | Ti | Others | Al | |

| Individual | Total | |||||||||

| max. 0.25 | max. 0.35 | max. 0.05 | max. 0.03 | max. 0.03 | max. 0.05 | max. 0.05 | max. 0.03 | max. 0.03 | - | min. 99.60 |

| 1070 transformer aluminum strip Chemical composition(%) | ||||||||||

| Si | Fe | Cu | Mn | Mg | Zn | V | Ti | Others | Al | |

| Individual | Total | |||||||||

| max. 0.20 | max. 0.25 | max. 0.04 | max. 0.03 | max. 0.03 | max. 0.04 | max. 0.05 | max. 0.03 | max. 0.03 | - | min. 99.70 |

| 1350 transformer aluminum strip Chemical composition(%) | |||||||||||

| Si | Fe | Cu | Mn | Cr | Zn | Ca | V+Ti | B | Others | Al | |

| Individual | Total | ||||||||||

| max. 0.10 | max. 0.40 | max. 0.05 | max. 0.01 | max. 0.01 | max. 0.05 | max. 0.03 | max. 0.02 | max. 0.05 | max. 0.03 | max. 0.10 | min. 99.50 |

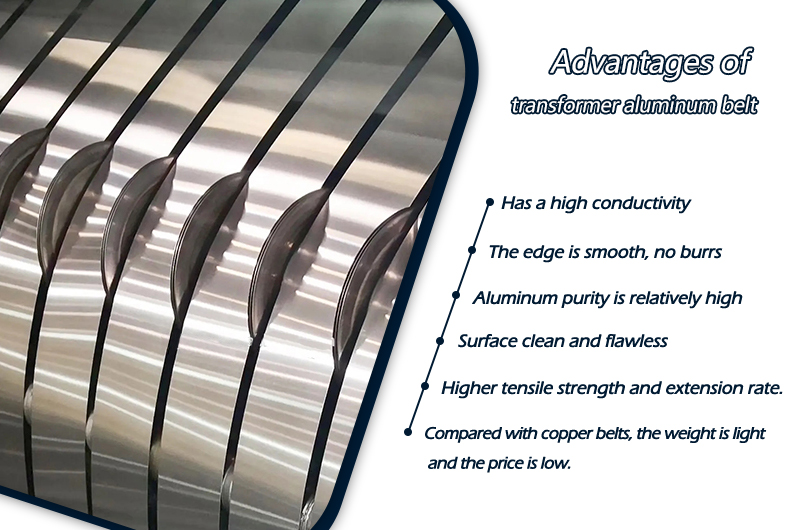

The Features and advantages of transformer aluminium foil

1) With high electrical conductivity Transformer aluminium foil strip uses high-quality pure aluminum as raw material, which has the characteristics of high conductivity.

2) With Smooth edges and no burrs Transformer aluminum foil strip is treated with special edge, and the edge is relatively smooth and free of burrs.

3) The purity of aluminum is relatively high Transformer aluminum foil adopts high-purity aluminum as raw material, and the aluminum content can reach more than 99.6%, which has unparalleled electrical conductivity of other series of aluminum strips.

advantages of transformer aluminum strip

4) Good surface processing, uniform texture, clean and defect-free The surface of the transformer aluminum strip is a rolled surface, which is well processed, uniform in texture, free from scratches, metal and non-metallic indentations, oil spots, local deformation and other defects.

5) With high tensile strength and elongation.

6) Compared with copper strip, thin aluminum strips is light in weight and low in price. Copper strip has always been the key raw material for the manufacture of transformer windings, but due to the high price of copper strip, many transformer manufacturers use light weight (the proportion of aluminum and copper is 1:6) and low price in order to reduce costs and improve market competitiveness. (The price of copper is about 3 times that of aluminum strip price), and aluminum strips with similar quality to copper strips replace copper strips, which also makes aluminium strip uses products more and more used in the transformer production industry.

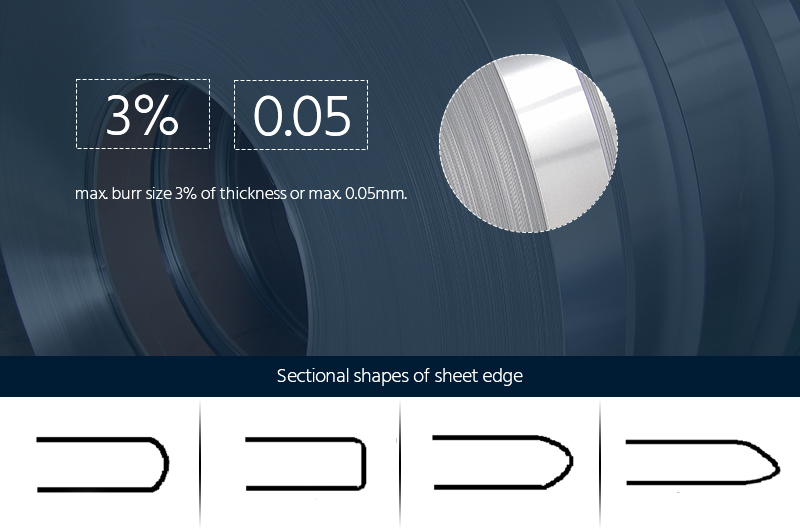

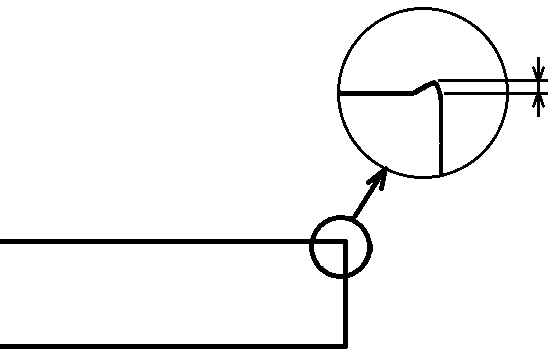

The edge of transformer aluminum foil shall be in accordance with following conditions.

burr size 3% of thickness or max. 0.05mm.

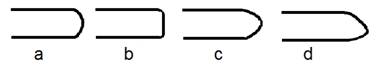

| The edge quality shall comply to table below. | |

|---|---|

| Sectional shapes of sheet edge | |

| Accept |

|

| Reject |

|

The Mechanical properties and electric conductivity of Aluminum transformer strip

| Thickness | Tensile strength N/mm2(MPa) | Elongation % | Bending 180 buckling inside radius | Electric conductivity % at 20°C |

|---|---|---|---|---|

| Over 0.2 to 0.5 |

|

20min. |

|

|

| Over 0.5 to 0.8 | 55--95 | 25min. | Close contact | 61.5min. |

| Over 0.8 to 1.5 | 30min. | |||

| Over 1.5 to 2.0 | 30min. | |||

| Over 2.0 to 3.0 | 35min. |

The dimensional tolerances requirements for Aluminium transformer strip

| Thickness | Tolerance in thickness | Tolerance in width | |||

| Guaranteed value | - | 20 to 300 | Over 300 to 600 | Over 600 to 1650 | |

| Over 0.2 to 0.5 | ±0.02 |

|

|

|

|

| Over 0.5 to 0.8 | ±0.03 | ||||

| Over 0.8 to 1.3 | ±0.04 | ±0.3 | ±0.5 | ±1.0 | |

| Over 1.3 to 2.0 | ±0.04 | ||||

| Over 2.0 to 3.0 | ±0.05 | ||||

The Application of aluminum foil for transformer winding

Aluminum foil for transformer winding is the key raw material for the manufacture of aluminium transformer windings, mainly used in dry-type transformers, belt converters, large transformers, solar energy, power industries, etc.

application of aluminum foil for transformer winding

1060 transformer aluminium strip(Aluminium strip for transformer)

1) Introduction of 1060 transformer aluminium strip(Aluminium strip for transformer)

Aluminum strips and foils for dry-type transformers generally use 1060 transformer aluminium strip whose aluminum content reaches more than 99.6%, also known as pure aluminum strips, and belongs to a commonly used series in the aluminum strip family. The advantages of this series of aluminum sheets and strips: the most commonly used series, the production process is relatively simple, the technology is relatively mature, and the price has a huge advantage compared to other high-grade alloy aluminum sheets. 1060 Aluminium strip for transformer has good elongation and tensile strength, and can fully meet the conventional processing requirements (stamping, stretching) and high formability. It is industrial pure aluminum with high plasticity, corrosion resistance, electrical conductivity and thermal conductivity.

2)The Specifications of 1060 aluminium foil for transformer winding

Material: 1060-O Temper Thickness: 0.2mm--3.0mm, Width: 20mm-1650mm. Uses: 1060 transformer aluminium foil Mainly used in high and low voltage windings of dry-type transformers as conductive materials. Description: 1060 aluminium foil for transformer Smooth surface without scratches. The edge can be chamfered (rounded corners, rounded edges), without burrs, which is better than the national standard. The resistivity is less than or equal to 0.028. Packaging: vertical packaging or horizontal packaging. Henan Signi Aluminium started from the melting and casting process of transformer aluminum strip, and strictly controlled the process links such as melting and casting, rolling, heat treatment, and finished product shearing. By controlling the alloy composition and optimizing the rolling and annealing process, the product achieves high electrical conductivity and mechanical properties. At present, our company has established internal standards for aluminum strips for transformers, and formed a complete production process system. It has achieved the key goals of 100% qualified rate of product warehousing and more than 98% customer satisfaction.