Specification

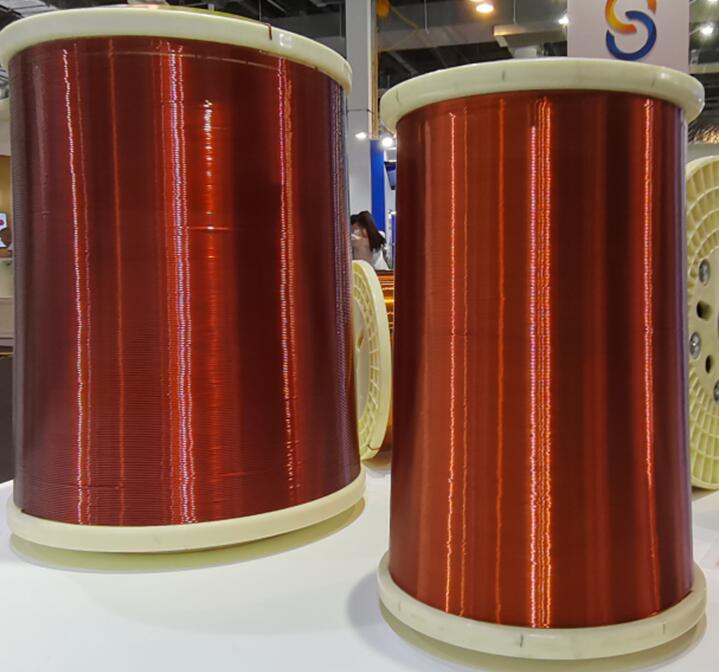

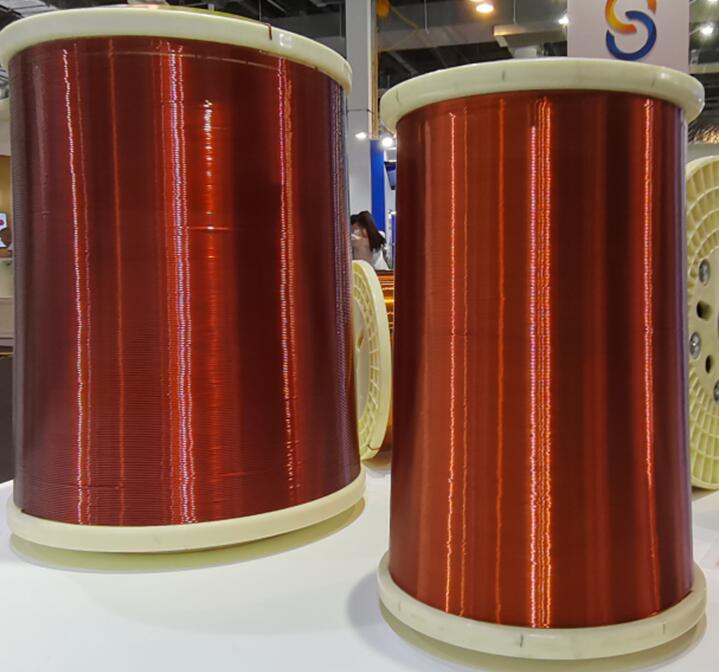

Refrigerant resistant enameled aluminum wire

Source:Original

Editing:frank

Time:2021-05-10 17:15

Enameled aluminum wire is a main type of winding wire, which consists of two parts: conductor and insulating layer. After annealing and softening, bare wire is painted and baked for many times. Most of the existing winding wires are enameled copper wire. However, due to the high cost of copper wire, aluminum wire is used to replace copper wire. The melting point of aluminum is low, so the enameled aluminum wire needs to have good heat dissipation performance, And the insulation layer of the existing winding wire has poor effect of refrigerant resistance, which affects the performance of winding wire.

The refrigerant resistant enameled aluminum wire produced by signi aluminum includes aluminum conductor. The outer drop of the aluminum conductor is coated with the cold resistant drop dip paint. The internal fixation of the paint is fixed with a heat sink, and the outer part of the paint is wrapped with polyamide film, and the outer winding of the polyimide film is covered with glass wire layer, The outer part of the glass fiber layer is coated with a refrigerant resistant paint, and the outer part of the refrigerant resistant paint is coated with weldable polyester imimide paint. Preferably, the glass fiber layer has two layers, and the winding direction of the two glass fiber layers is opposite.

The total thickness range of polyimide film, glass fiber layer, refrigerant resistant paint and weldable polyester imimide paint is between 0.4-0.6mm.

The refrigerant resistance enabled aluminum wire is made of the refrigerant resistant material through the coordination between the cold resistant drop dip paint, polyimide film and refrigerant resistant paint. The effect of the refrigerant resistance of the coating aluminum wire is triple guaranteed, the effect of the refrigerant resistance is good and the performance of the coating aluminum wire is improved.

The cooling pipe is hollow in the interior through the cooperation of aluminum conductor, paint dip coating and heat pipe of cooling medium resistance, which is convenient for cooling the interior of the paint. Moreover, several aluminum wires with small diameter are used to replace the whole aluminum wire with larger straight diameter, which can transmit heat from aluminum conductor more

The refrigerant resistant enameled aluminum wire produced by signi aluminum includes aluminum conductor. The outer drop of the aluminum conductor is coated with the cold resistant drop dip paint. The internal fixation of the paint is fixed with a heat sink, and the outer part of the paint is wrapped with polyamide film, and the outer winding of the polyimide film is covered with glass wire layer, The outer part of the glass fiber layer is coated with a refrigerant resistant paint, and the outer part of the refrigerant resistant paint is coated with weldable polyester imimide paint. Preferably, the glass fiber layer has two layers, and the winding direction of the two glass fiber layers is opposite.

The total thickness range of polyimide film, glass fiber layer, refrigerant resistant paint and weldable polyester imimide paint is between 0.4-0.6mm.

The refrigerant resistance enabled aluminum wire is made of the refrigerant resistant material through the coordination between the cold resistant drop dip paint, polyimide film and refrigerant resistant paint. The effect of the refrigerant resistance of the coating aluminum wire is triple guaranteed, the effect of the refrigerant resistance is good and the performance of the coating aluminum wire is improved.

The cooling pipe is hollow in the interior through the cooperation of aluminum conductor, paint dip coating and heat pipe of cooling medium resistance, which is convenient for cooling the interior of the paint. Moreover, several aluminum wires with small diameter are used to replace the whole aluminum wire with larger straight diameter, which can transmit heat from aluminum conductor more

RELATED READ:

- Foil for electrolytic capacitors2015.3.19

- Copper-Clad Aluminum Wire (CCA)2015.3.19

- 5052 aluminum strip for shutters2015.3.19

- Application of aluminum semi-finished products in e2015.3.19

- Copper clad aluminum enamelled round wire2015.3.19