Fibreglass Round Aluminum Wire

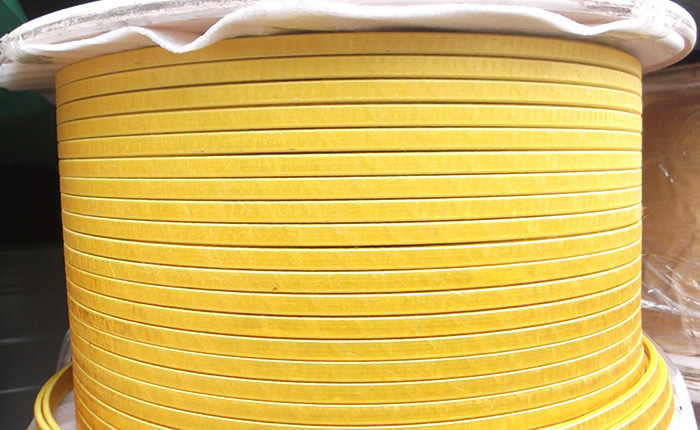

Fibreglass Polyester Film Insulated Covered Round & Flat Aluminum Strip Wire

1. Production introduction:

Signi fibreglass PEI PET film insulated covered round & flat aluminum strip wire, it is wrapped by PET film or PEI film, after that wrapped by single or double fibre, with the required temperature resistance index of insulating varnish for dipping, baking processing, so that the glass fiber, glass fiber and film, conductor, form a whole body. Signi fibreglass PEI PET film insulated covered round & flat aluminum strip wire product has a high resistance to high voltage breakdown value, 130, 155, 180, four 200 grades, widely used in reactors, transformers, motors, or other similar electrical appliance products.

2. Product specs:

Signi fibreglass PEI PET film insulated covered flat aluminum strip wire

Thickness: 0.8mm--7mm

Width: 2.0mm--16.0mm

Temp Class : 155, 180

Standard : IEC,NEMA,GB,JIS

Temp Class : 155, 180

Standard : IEC,NEMA,GB,JIS

Signi fibre PEI PET film insulated round aluminum strip wire

Diameter: 1.7mm--6mm

Resistivity : copper 20℃<=0.017241Ω(mm)^2/m , Aluminum 20℃<=0.028000Ω(mm)^2/m

Package : PT-25, PT-30,30kg/50kg/150kg wooden Spool according to customers requirements

Resistivity : copper 20℃<=0.017241Ω(mm)^2/m , Aluminum 20℃<=0.028000Ω(mm)^2/m

Package : PT-25, PT-30,30kg/50kg/150kg wooden Spool according to customers requirements

Special spec can be made as well if request.

3.Signi fibreglass PEI PET film insulated covered round & flat aluminum strip wire follow the standard of GB5584.3-2009, electrical resistivity at 20℃ is above 0.028 Ω-mm²/m.

4. Insulation thickness and voltage breakdown value shall follow the below standard.

3.Signi fibreglass PEI PET film insulated covered round & flat aluminum strip wire follow the standard of GB5584.3-2009, electrical resistivity at 20℃ is above 0.028 Ω-mm²/m.

4. Insulation thickness and voltage breakdown value shall follow the below standard.

Feature :

Wrapped smoothly and tightly, without missing layers, bright and clean

Material :

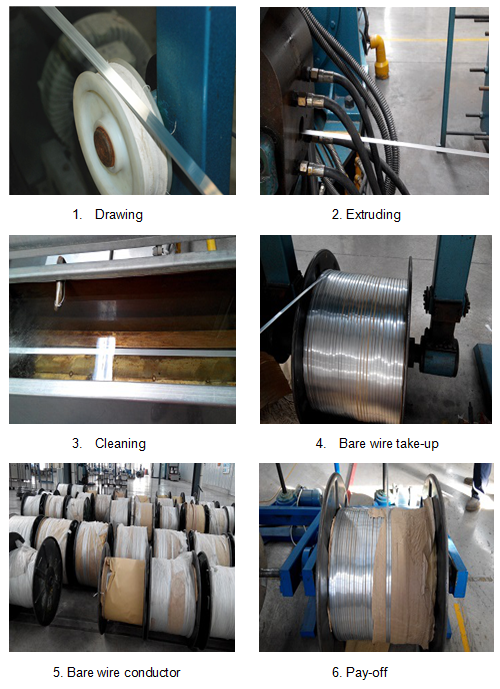

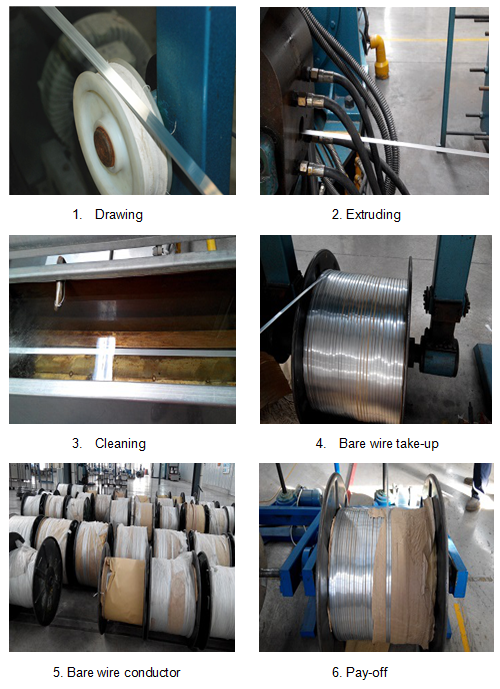

Drawing or extruding bare wire confirm to National Standard. smooth surface, no defects

| Product | Insulation thickness/mm | Tolerance% |

Minimum breakdown voltage value/V |

|---|---|---|---|

|

Fibreglass PEI PET Film Insulated Covered Round & Flat Aluminum Strip Wire |

0.20 | ±15% | 2500 |

| 0.30 | -15% | ||

| 0.40 | |||

| 0.50 | 5000 | ||

| 0.60 | |||

| 0.70 | 6000 | ||

| 0.80 | |||

| 0.90 |

Applicaton of Fiber Glass Covered Wire:

The product is widely used in transformers, electromagnets, welders or other similar products, medium and large electrical appliances winding.

Production Process :

Production Process :

Packing Process :

Step 1 : Plastic film and kraft paper packaging, ensure neat and clean, dry ;

2. Wooden box packaging, the outside fixed with packing belt, safe and reliable ;

RELATED READ: