Specification

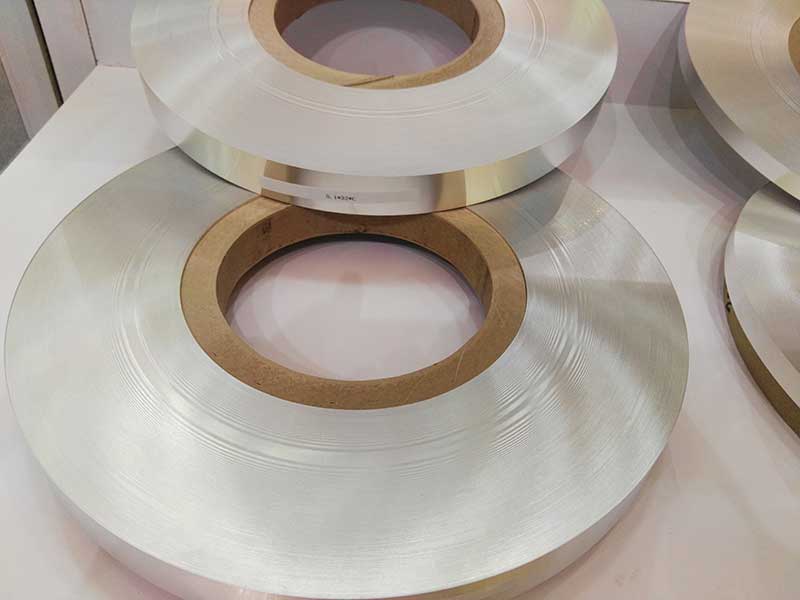

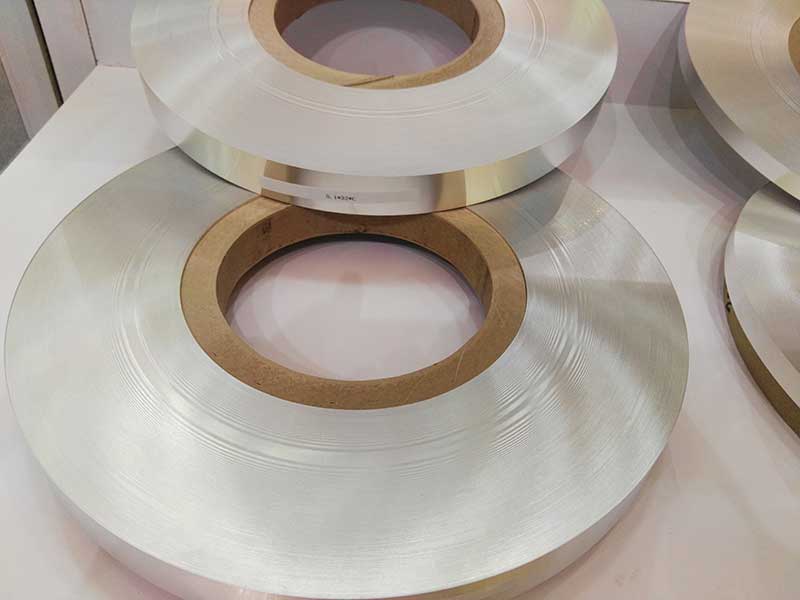

Aluminum transformer winding material

Source:Original

Editing:frank

Time:2020-12-07 17:15

The dry-type transformer is mainly composed of an iron core composed of silicon steel sheets and an inductance cast coil. An insulating tube is placed between the high and low voltage coils to increase electrical insulation, and the coil is supported and restrained by a spacer.

The high and low voltage windings are made of aluminum transformer winding materials, and epoxy resin is poured and cured in a vacuum to form a high-strength glass fiber reinforced plastic body structure. There are F and H insulation grades. The windings of most dry-type transformers gradually use aluminum foil structures. Because this structure can completely improve the cooling performance and mechanical strength of the dry-type transformer, and it can also greatly improve the pressure resistance of the dry-type transformer.

Windings are the main circuit channels of dry-type transformers and are mainly made of paper-wrapped insulated flat wires or round wires. Aluminum transformer winding materials: enameled aluminum wire, yarn-coated aluminum wire, fiber glass insulated aluminum wire, paper insulated aluminum wire, the most commonly used enameled wire.

Dry-type transformers have the advantages of strong short-circuit resistance, small maintenance workload, high operating efficiency, small size, and low noise. They are often used in places with high performance requirements such as fire prevention and explosion protection. Dry-type transformers are widely used in local lighting, high-rise buildings, airports, terminals, CNC machinery and equipment, etc.

The high and low voltage windings are made of aluminum transformer winding materials, and epoxy resin is poured and cured in a vacuum to form a high-strength glass fiber reinforced plastic body structure. There are F and H insulation grades. The windings of most dry-type transformers gradually use aluminum foil structures. Because this structure can completely improve the cooling performance and mechanical strength of the dry-type transformer, and it can also greatly improve the pressure resistance of the dry-type transformer.

Windings are the main circuit channels of dry-type transformers and are mainly made of paper-wrapped insulated flat wires or round wires. Aluminum transformer winding materials: enameled aluminum wire, yarn-coated aluminum wire, fiber glass insulated aluminum wire, paper insulated aluminum wire, the most commonly used enameled wire.

Dry-type transformers have the advantages of strong short-circuit resistance, small maintenance workload, high operating efficiency, small size, and low noise. They are often used in places with high performance requirements such as fire prevention and explosion protection. Dry-type transformers are widely used in local lighting, high-rise buildings, airports, terminals, CNC machinery and equipment, etc.

Previous :Aluminum windings in transformers

RELATED READ: