Specification

super enameled aluminum flat wire

Source:Original

Editing:frank

Time:2021-07-05 18:09

Super enameled aluminum flat wire with conductor cross-section less than 10.00 mm2 has been widely used in the field of micro motor and new energy vehicle. By the end of 2019, the total sales volume of new energy vehicles in the whole year is about 1.26 million, and the average new energy vehicle uses 3-4 kg super enameled aluminum flat wire, with a total annual line consumption of about 4000 tons. With the popularity of new energy vehicles, the supporting facilities charging piles are also installed in the compactly. At present, the number of charging piles in China has reached 1.219 million, and the average charging pile uses small-scale paint coated flat wires with a sectional area of 3-5 kg conductor less than 8.00 mm2, with a total of 5000 tons of wires per year. So, super enameled aluminum flat wire it has a broad development prospect in the field of new energy vehicles. In addition, from the current efficiency of motor products, the efficiency of more than 90% of motor products in China is 2% ~ 3% lower than the advanced level abroad. To improve the efficiency, it is necessary to improve the slot full rate of the motor. super enameled aluminum flat wire will undoubtedly be a good choice.

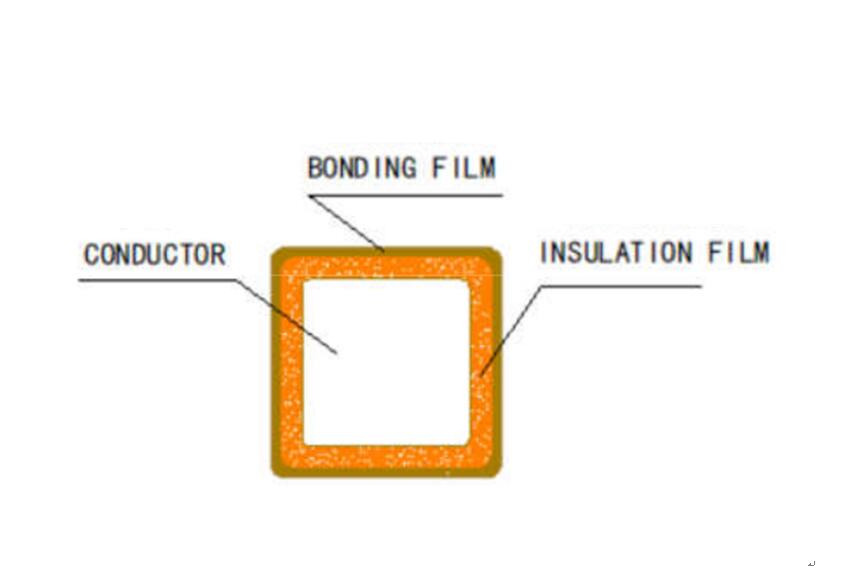

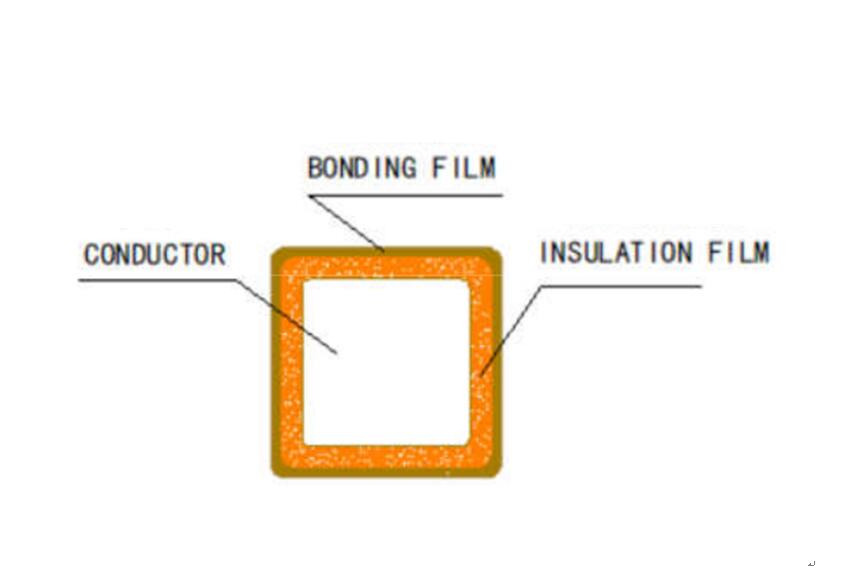

Signi Aluminum is engaged in super enameled aluminum flat wire production and processing, mastering the core technology, have mature fine enamelled square wire production line, the product is complete, the square wire range is 0.10-0.60mm, the conductor materials is aluminum, , the insulation film varieties are polyester-imide, polyamide-imide and polyimide and its black paint film, thermal rating include 155, 180, 200, 220 and 240.

Signi could produce according to IEC60317、NEMA MW1000 and JIS C3202 standards, or customized according to the special requirements of customers.

Advantages of super enameled aluminum flat wire :

1. Increase thin the volumetric occupancy ratio, increase tin powder and crease in coil size.

2. Increasing surface area is conducive to heat dissipation and reducing skin effect.

Technical data of precision self bonding enamelled square wire:

Signi Aluminum is engaged in super enameled aluminum flat wire production and processing, mastering the core technology, have mature fine enamelled square wire production line, the product is complete, the square wire range is 0.10-0.60mm, the conductor materials is aluminum, , the insulation film varieties are polyester-imide, polyamide-imide and polyimide and its black paint film, thermal rating include 155, 180, 200, 220 and 240.

Signi could produce according to IEC60317、NEMA MW1000 and JIS C3202 standards, or customized according to the special requirements of customers.

Advantages of super enameled aluminum flat wire :

1. Increase thin the volumetric occupancy ratio, increase tin powder and crease in coil size.

2. Increasing surface area is conducive to heat dissipation and reducing skin effect.

Technical data of precision self bonding enamelled square wire:

RELATED READ: